EMPUR > en > Components > Manifold technology

EMPUR® manifold technology

Heat distribution with a system

At our Buchholz-Mendt location, EMPUR® produces high-quality manifolds and special solutions made from brass and stainless steel for client-specific requirements.

The structural design of our new manifold generation has been optimised and now offers a significantly reduced assembly effort for specialised craftsmen in combination with the EMPUR® manifold cabinets, which have also been adjusted. With the specially developed quick manifold assembly technology, the manifolds are simply suspended in the guide rails of the manifold cabinet and fixed using two fillister head screws.

Thanks to extensive manifold accessories, we enable the right connection in every situation for a perfectly adapted system – ranging from connection sets and heat volume measurement sets to line regulating or zone valves, pointer thermometers and restrictors.

Our manifold technology at a glance:

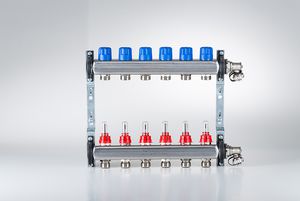

PUR-THERM® brass manifolds

Our system manifolds made of a brass section pipe with flow rate indicators and integrated valves are pre-assembled on the manifold holder with sound insulation inserts at our factory. The installation width is minimal as a result of the compact valve clearance.EMPUR® actuators can be installed directly instead of the blue protection cap on the return flow valves. The feed flow valves underneath are equipped with controllable and adjustable flow rate indicators (0-5 l/min). The two enclosed manifold end-pieces with a reducer for filling, bleeding and draining the heating circuit manifold can be rotated and are supplied in the bag for optional assembly on the right or left of the manifold.

BENEFITS

- Reduction of assembly effort through the delivery of pre-assembled manifolds

- Compact valve clearance for a small installation width

- Quick manifold assembly in EMPUR® manifold cabinets through adjusted suspension rails

- Simple and exact positioning of the manifold in the manifold cabinet, continuously adjustable in a horizontal direction

- Extensive accessories for expansion

- All system components from a single source and manufactured in-house – Made in Germany quality

EMPUR® control manifolds

EMPUR® control manifolds are suitable for variable or constant flow temperature control in combination with control set V or K for the hydraulic integration of low-temperature floor heating in existing heating systems.The latest generation of EMPUR® control manifolds is manufactured from 1” brass profile pipe. They are completely pre-assembled on manifold holders with sound insulation inserts and are equipped as standard with a high-efficiency pump, fine control valve, valve body for rule set, thermoseparator, 2 shut-off valves, 2 rinsing, filling and drainage valves as well as a pointer thermometer.

EMPUR® actuators can be installed directly instead of the blue protection cap on the return flow valves. The feed flow valves underneath are equipped with controllable and adjustable flow rate indicators (0-5 l/min).

BENEFITS

- Reduction of assembly effort through the delivery of pre-assembled manifolds

- Compact valve clearance for a small installation width

- Ideal for variable or constant flow temperature control in combination with control set V or K

- Possibility of subsequent hydraulic integration of the low-temperature floor heating in existing heating systems when modernising

- Hydraulic decoupling of the heat generator using the supplied thermoseparator

- Prevention of excess temperatures in the system using an overheat thermostat (accessories)

- Simple and safe limitation of the water volumes using an adjustable fine control valve

- Quick manifold assembly in the EMPUR® "Plus" manifold cabinets through adjusted suspension rails

- Simple and exact positioning of the manifold in the manifold cabinet, continuously adjustable in a horizontal direction

- Specially adapted accessories for an optimal connection to the heating system

- All system components from a single source and manufactured in-house – Made in Germany quality

Geniax complete manifolds

The Wilo-Geniax heat distribution system is a flexible surface heating and control system which enables appropriate, customised heating of individual rooms in residential and non-residential buildings.A small, highly-efficient glandless circulation pump is provided on the manifold for each heating circuit, which often makes the central heating pump obsolete. The decentralised pumps are controlled by a central system, the Geniax server. This server receives its information regarding changing actual and desired temperature values from operating devices with integrated sensors that are networked with one another by the Geniax BUS.

The combination of software-controlled temperature regulation and decentralised pumps at the heat transfer panels ensures that each individual room is provided with the exact required heat.

Besides the benefits which include best possible energy efficiency and increased heating comfort, the system is characterised by high functionality and flexibility.

The HKV-G stainless steel or brass manifold is supplied completely pre-assembled and connected in the "Top standard plus" or "Exclusiv plus" manifold cabinet.

BENEFITS:

- Easy to install thanks to completely pre-assembled EMPUR® Geniax complete manifolds

- Automatic hydraulic regulation through the system

- No need for regulation or circuit control valves

- Direct access with SysManager

- Appropriate and automatic regulation by a centralised control system

- Suitable for combination with regenerative heating systems and/or solar thermal energy systems

- Both cooling and heating possible

- Maximum ease of operation in terms of flexibility, regulation ability, quick heating and temperature lowering during the night

- Automatically switches off the heating system when a window is opened

- Sustainability due to energy savings

- The requirements of the Energy Savings Regulation (EnEV) 2014 / DIN V 18599-11 (building automation) are complied with

- Reconstruction Loan Corporation (kfW) subsidy possible

PUR-THERM® manifold cabinets

PUR-THERM® manifold cabinets provide the perfect location for manifolds and control stations. PUR-THERM® manifolds can be installed the traditional way using the “Top Standard” version as a cabinet on the wall and the “Exclusiv” version as a cabinet integrated into the wall.

The “Exclusiv superflach (super-flat)” manifold cabinet enables manifold installation into narrow light-weight and dry walls. The large manifolds, control stations and control manifolds are installed in the “Top Standard plus” manifold cabinet for on-the-wall mounting or “Exclusiv-plus” for wall-integrated mounting.

The newest generation of EMPUR® manifold cabinets has been completely reworked and is manufactured from galvanised and foil-coated sheet steel. These offer adjusted suspension rails for the EMPUR® heating circuit manifolds. With the specially developed ‘quick manifold assembly technology’, the manifolds are simply suspended in the guide rails of the manifold cabinet and fixed with two screws.

Additional benefits of the new generation of manifold cabinets include easy connection of the primary connections, time savings when feeding through electrical connection cables and, of course, secure and flexible mounting options.

The newest generation of EMPUR® manifold cabinets has been completely reworked and is manufactured from galvanised and foil-coated sheet steel. These offer adjusted suspension rails for the EMPUR® heating circuit manifolds. With the specially developed ‘quick manifold assembly technology’, the manifolds are simply suspended in the guide rails of the manifold cabinet and fixed with two screws.

Additional benefits of the new generation of manifold cabinets include easy connection of the primary connections, time savings when feeding through electrical connection cables and, of course, secure and flexible mounting options.

BENEFITS

- Optimal suspension rails for the quick manifold installation of the EMPUR® system manifold

- High resistance of the surfaces through quality workmanship and an environmentally friendly film coating

- Simple connection of the primary connections through optimised lateral punch-outs

- Time savings when feeding through connection cables as a result of pre-punched openings

- Secure and flexible assembly of the manifold cabinets through various mounting Options

- Individual, pre-assembled complete manifold solutions available on request

You can find further current sales or technical product documents as PDF for download HERE.